Contrasting the Best Welding Shirts: Which One Provides the Best Defense?

Contrasting the Best Welding Shirts: Which One Provides the Best Defense?

Blog Article

Discovering the Various Designs and Products Made Use Of in Welding Shirts to Improve Comfort and Safety And Security During Welding Tasks

The choice of welding shirts plays an important role in balancing comfort and security for welders in diverse atmospheres. With alternatives ranging from long-sleeve to short-sleeve styles, and materials that prioritize breathability and fire resistance, understanding the nuances of these garments can considerably influence performance. Variables such as ergonomic fit and strengthened seams even more add to a welder's performance and well-being. As we examine the details styles and products available, it ends up being important to take into consideration just how these options can eventually influence not simply comfort, but likewise safety and security on the work.

Importance of Welding Shirts

Welding shirts play an important duty in making sure the security and comfort of professionals in the welding market. These specialized garments are designed to shield welders from the various dangers related to their workplace. High temperature levels, sparks, and molten steel are usual threats that can result in severe injuries if correct safety garments is not made use of.

Along with physical security, welding t-shirts are crafted from products that provide fire resistance, which is vital for securing welders versus potential burns. The option of textile dramatically affects the t shirt's longevity and efficiency, with products such as cotton, denim, and specialized synthetic fibers being preferred choices.

Furthermore, welding tee shirts are designed to offer comfort during lengthy hours of labor. Attributes such as moisture-wicking properties and breathable fabrics aid handle sweat and temperature, permitting improved emphasis and efficiency. The ergonomic design and fit of these t-shirts allow simplicity of movement, ensuring that welders can do their tasks without limitation.

Popular Designs of Welding Shirts

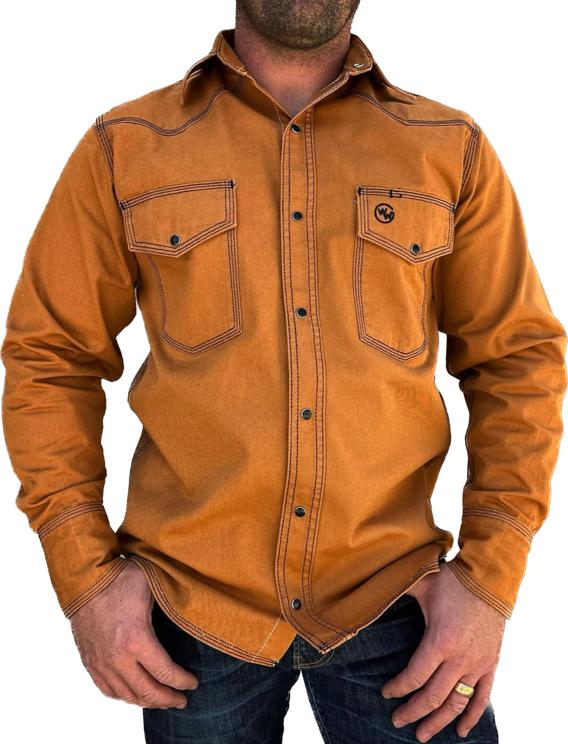

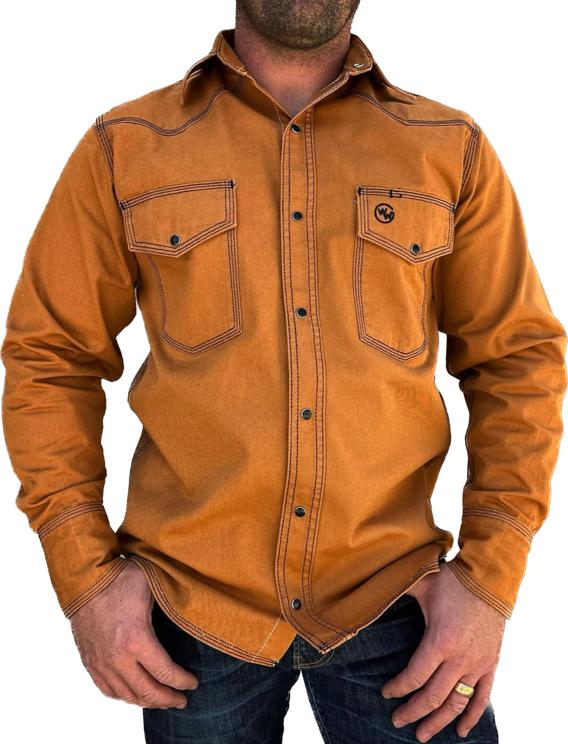

Numerous styles of welding t-shirts cater to the diverse demands of experts in the sector, each offering special attributes that enhance capability and comfort. One prominent style is the long-sleeve welding t-shirt, made to provide maximum coverage and shield the arms from triggers and warmth. These tee shirts usually include strengthened sewing to stand up to the roughness of welding tasks.

An additional usual design is the short-sleeve welding t shirt, which supplies breathability and comfort in warmer environments while still adhering to safety and security standards. Some experts favor button-up welding t shirts, as they permit simple changes in temperature level and can be combined with safety gear.

In addition, lots of welding shirts feature high-visibility styles, usually integrating bright colors or reflective strips to make sure that welders continue to be noticeable in dimly lit conditions. This is specifically essential in industrial setups where safety and security is extremely important.

Finally, welding tee shirts with pockets and tool loops are increasingly popular, giving welders with hassle-free storage for important tools and personal things. These designs integrate security and functionality, Homepage making them crucial for professionals in the welding market.

Trick Materials for Convenience

Cotton is a prominent choice because of its gentleness and breathability. It permits appropriate air movement, decreasing sweat build-up during intense tasks. 100% cotton may not be the ideal alternative for severe conditions, as it can retain warmth and moisture.

Synthetic blends, such as polyester and nylon, are increasingly preferred for their moisture-wicking capabilities. These materials draw sweat away from the skin, keeping the wearer completely dry and comfy (Best Welding Shirts). Furthermore, synthetic fabrics often have improved resilience, standing up to deterioration from the roughness of welding tasks

Some manufacturers are currently incorporating innovative textiles like spandex for included stretch, enabling enhanced mobility. This adaptability is vital for welders, that require to navigate tight areas and do elaborate movements.

Ultimately, the appropriate combination of products can substantially boost convenience, making it vital for welders to consider their certain demands when selecting a welding shirt.

Flame-Resistant Features

Choosing the right welding tee shirt not just involves considering convenience and breathability however likewise guaranteeing adequate security against prospective threats, especially fires and stimulates. Flame-resistant (FR) features are necessary for keeping security in welding environments, where direct exposure to heats and molten steel can pose considerable risks.

Welding t-shirts designed with flame-resistant products are usually made from specialized materials that have been treated or inherently have residential properties to stand up to ignition and decrease burn injury. Typical products include cotton blends with FR surfaces, Nomex, and Kevlar, which give reliable obstacles against fires and thermal hazards. These textiles often undergo extensive screening to meet industry requirements, such as ASTM F1506 or NFPA 701, ensuring they use reputable security.

In enhancement to material choice, the style of the welding tee shirt plays a critical role in its flame-resistant capabilities. Attributes such as enhanced joints, high browse around here collars, and flame-resistant buttons or zippers contribute to overall safety and security by lowering the threat of triggers entering the garment. Investing in a welding shirt with robust flame-resistant features is important for protecting the wearer versus the inherent threats of welding jobs, ensuring both comfort and defense on the work.

Tips for Picking the Right Tee Shirt

Considering the unique demands of welding tasks, selecting the best welding shirt requires mindful attention to several key factors. Primarily, prioritize products that offer fire resistance, such as cotton, dealt with cotton, or artificial blends especially created for welding environments. Guarantee that the t shirt meets suitable safety and security requirements, such as those set by the American National Specification Institute (ANSI) or the National Fire Protection Association (NFPA)

Fit is an additional essential facet; select a t-shirt that permits liberty of movement without being extremely loose, as loose material can catch on equipment or stir up. Additionally, select long sleeves to protect the arms from sparks and heat (Best Welding Shirts). Try to find features such as enhanced sewing and sturdy seams, which boost the tee shirt's durability and endure the roughness of the work

In addition, consider the climate in which you'll be functioning. Tee shirts with moisture-wicking homes can assist manage body temperature and maintain you comfortable during lengthy hours. Last but not least, review the t-shirt's breathability and weight view it now to ensure it balances defense with comfort, permitting for sustained performance throughout your welding jobs.

Conclusion

In summary, the selection of ideal welding t-shirts plays a crucial role in making sure both convenience and safety and security throughout welding jobs. Different designs, consisting of long-sleeve and short-sleeve options, deal with varied atmospheres while vital products such as breathable materials and flame-resistant materials provide essential defense. Incorporating attributes like strengthened joints and ergonomic layouts better boosts movement. Ultimately, making notified selections regarding welding tee shirts substantially adds to a more secure and more efficient welding experience.

Report this page